Building Enclosure Assessment

School Superintendents and administrators have a lot to worry about. Safe and efficient operations of their school buildings should not be one of them. While construction standards and building codes are evolving year after year, older buildings – even those considered young in building terms – may not have been built with the features, materials, or techniques that are more commonplace today. Building Enclosure Assessments, like Energy Audits, utilize the same skills and employ the same processes necessary as Building Enclosure Commissioning services. This can help to identify areas of concern and uncover unseen issues that when remediated, can improve the performance and longevity of the existing building stock.

Background

FST Technical Services’ Commissioning Division (formerly Horizon Engineering Associates, LLC) was retained by the Cumberland Valley School District to perform an assessment of the building enclosure systems at an elementary school located in Cumberland County, PA.

The school was built around 1996 with recent renovations being performed between 2019 and 2022. The renovation project included the installation of new Heating, Ventilation, and Air Conditioning (HVAC) systems, as well as localized repairs to the exterior walls. Shortly after the installation of the new HVAC system, it was reported that the system was not performing as expected with regard to maintaining the interior conditions at the desired set points. It was suspected that these performance issues may be caused by deficiencies in the building enclosure that are potentially imposing higher-than-expected heating and cooling loads on the HVAC system. The goal of this study was to evaluate the condition of the building enclosure to identify any deficiencies that may be causing the performance issues experienced by the HVAC system.

Building Enclosure Assessment Process

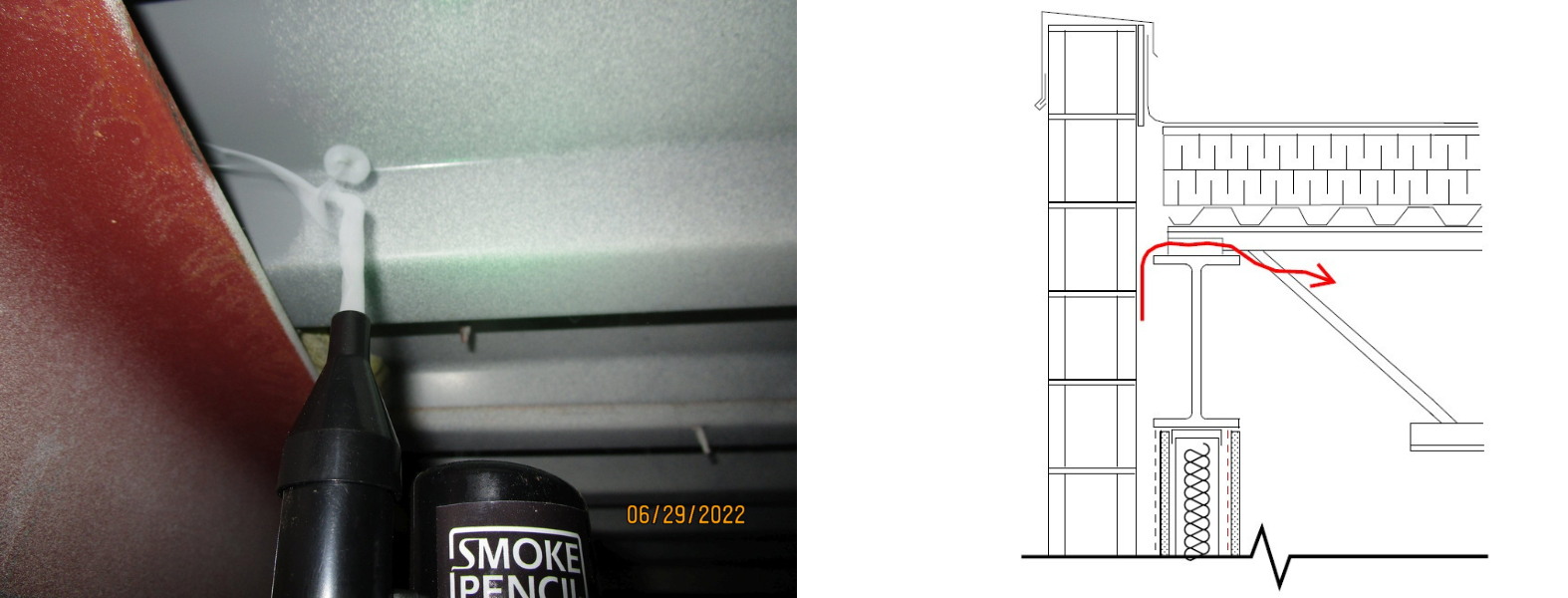

Just like Existing Building Commissioning, the Building Enclosure Assessment process begins with a planning phase aimed at gathering the necessary information to understand the building, its construction characteristics, and the owner’s operating requirements. This was primarily carried out by reviewing available plans, specifications, drawings, and other documents supplemented by discussions with facilities management personnel familiar with the operations of the building and the issues that are of concern. The initial walk-through of the buildings and a deeper investigation phase were carried out on the same day although for more complex problems and larger buildings, this phase of the process can be longer and can include multiple areas of investigation. During the investigation, FST performed visual observations of the interior and exterior of the building, used a smoke-generating device to help trace airflow, and used an infrared camera to identify and document potential air leakage points.

Construction Details

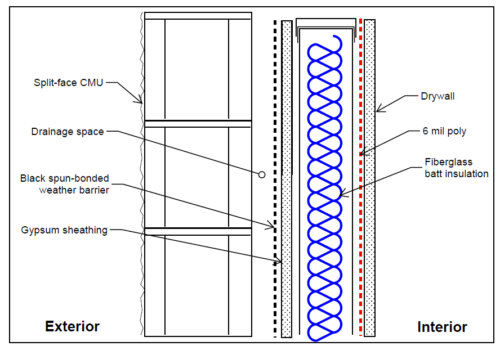

The exterior wall assembly consists of a split-faced Concrete Masonry Unit (CMU) veneer over a steel stud backup wall. We performed a small exploratory opening in the interior drywall in a concealed location to review the wall construction. The wall assembly was observed to consist of the following and as shown in the sketch below:

- Fiberglass batt insulation in stud cavity

- Vapor barrier on the interior side of the wall behind the drywall

- Gypsum sheathing on the exterior side of the wall

- Black spun-bonded weather barrier membrane over exterior sheathing

- Split face CMU

The original design intent for the air barrier strategy is unknown, but it appears to have been part of an airtight drywall approach where the interior drywall provides the air barrier.

Findings

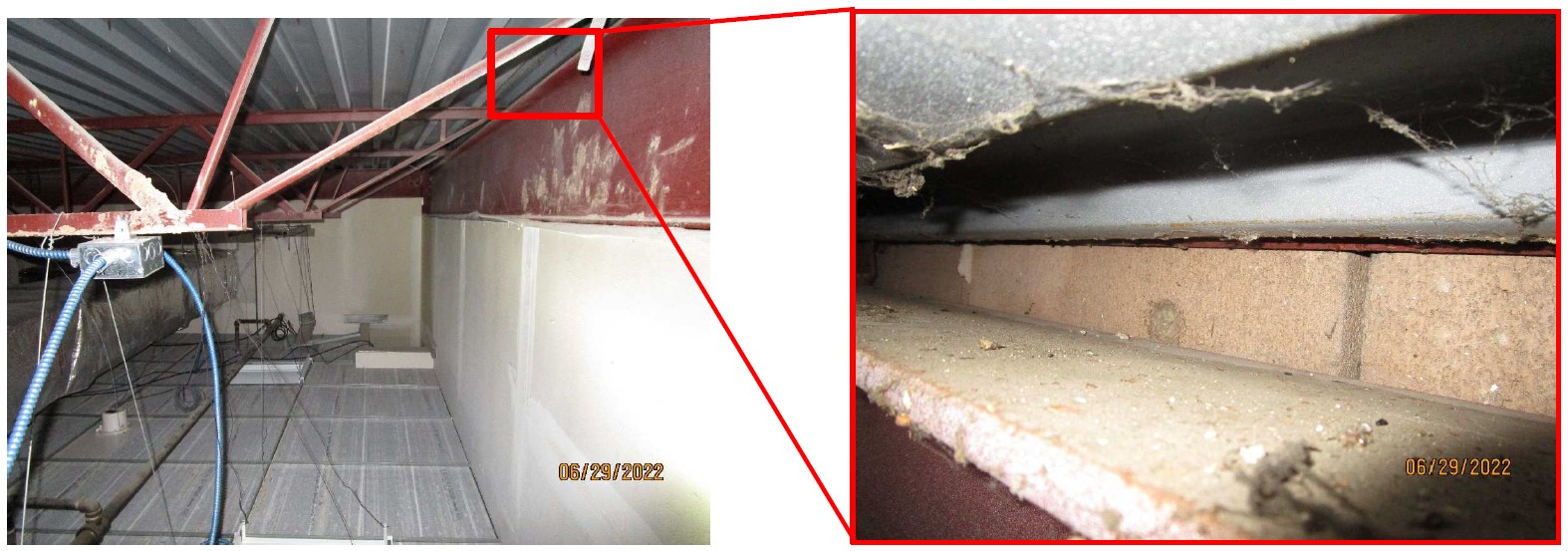

FST removed some of the suspended ceiling tiles to observe the conditions above the dropped ceiling. This was performed at the top of the 1st floor and the top of the 2nd floor (roof level). The drywall in the dropped ceiling terminates under spandrel beams (W-beams) that run all around the perimeter of the building. FST observed a systemic discontinuity in the air barrier along the spandrel beams. This occurs both at the 2nd floor and at the roof level. The drywall, vapor barrier, exterior sheathing, and weather barrier are interrupted at the underside of the spandrel beam. There is an open gap of about 2 inches between the top of the beam and the underside of the metal deck above. The back of the CMU veneer can be seen through that open gap.

This gap above the spandrel beam allows the unconditioned air present in the wall cavity to migrate, or leak, directly into the interior of the building. This significant deficiency was verified and documented visually using a smoke-generating device. The smoke was observed to alternatively infiltrate and exfiltrate to and from the drainage cavity fluctuating with the exterior wind direction. In summer the warm humid air will enter the building increasing the cooling demand on the HVAC system, and in the winter the reverse is true whereby warm air will exit the building increasing the heating requirements and undermining occupant comfort.

A continuous air barrier is now required in most of the current building codes and is considered to be an integral component in maintaining the thermal integrity of today’s buildings. The proper installation, sealing, connection, and transition of the air barrier across various substrates in even more important than it simply being one of the specified products in a wall assembly. When these schools were constructed, the use of air barrier materials and attention to construction details had yet to gain widespread acceptance.

Conclusion

Buildings are complex. No matter how simple any one system is there are always interactions among them. The design of the building enclosure and how it operates affects the ability of the mechanical systems to do their job. When the unexpected happens after a building is constructed, and long after the contractors have left the site, implementing a Building Enclosure Assessment using process-oriented methods and procedures can help successfully identify the contributing factors to an underperforming building. By engaging experienced and credentialed professionals who understand construction methods and building systems, building owners and operators can take steps to improve occupant comfort, minimize operating costs, and reduce the environmental impact associated with their buildings. By including Building Enclosure Commissioning in the project scope at the start of design and engaged throughout construction, deficiencies such as this could have been avoided.

FST Technical Services (FST) provides a broad range of Testing, Inspection, Certification, and Engineering Solutions needed throughout the building construction and operations life cycle. Our Building Envelope Commissioning services are modeled on National Institute of Building Science (NIBS) Guideline 3 with consideration for ASTM E2813: Standard Practice for Building Enclosure Commissioning using a quality focused process that verifies that all building envelope systems meet and exceed the performance targets set by the design team and ownership.